3D Printer Filaments: Definitions, Applications, and Tips

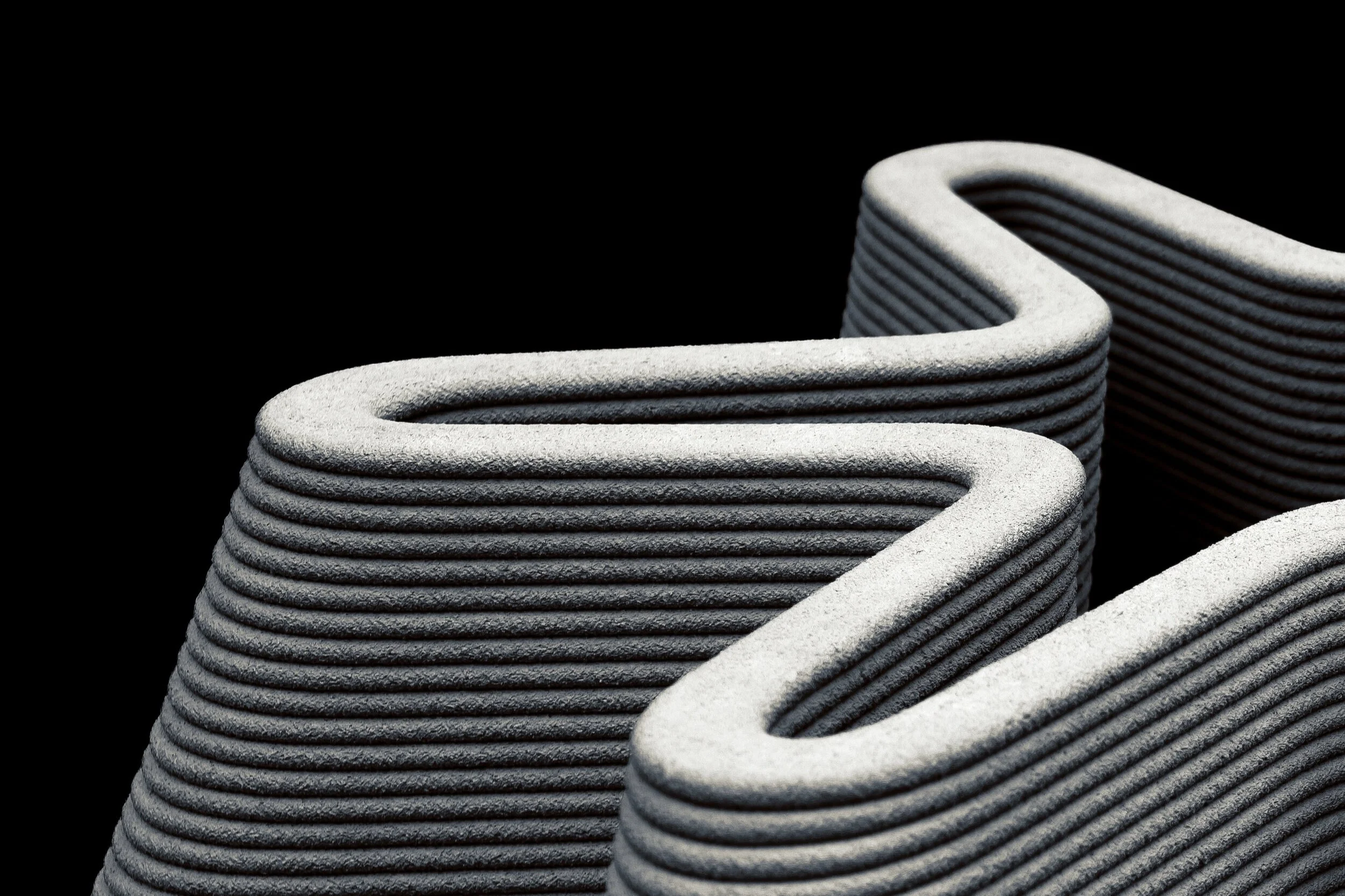

“Filament is the heart of Fused Deposition Modeling (FDM) 3D printing. The filament is fed into the extruder, heated, and deposited in specific locations layer by layer, eventually giving rise to a functional part that could be used for anything from validating a new design to repairing a Tesla. ”

Someone who is new to 3D printing may struggle to know what filament to use, when to use it, and how to use it. When I first bought my 3D printer, I didn’t really have any knowledge of filament types and bought the first roll I saw on Amazon. I made the mistake of buying a roll of ABS and gave myself a headache trying to figure out why the default settings for my printer were not working. Little did I know that all filament types need different settings and my printer’s default was set for PLA.

The benefits of knowing about different filament materials extend beyond just getting your printer to work however. Those who master different types of filament open up new worlds of application and use from their 3D printer. Learning the strengths, weaknesses, and uses of each new type of filament puts another tool in your engineering belt.

The following sections will go over three of the different types of filament (PLA, PETG, and Flexible), their composition, what they are useful for, and a few tips and tricks to using them. Please note that the tips given are general guidelines and will depend on the 3D printer being used. They may also differ printer to printer and even brand to brand or color to color.

General Tips

Keep all of your filaments in a dark, dry, sealed place. All types of filament are susceptible to moisture (some more than others-Flexible especially) and when they are exposed to humidity the filament can become saturated. The water in the filament evaporates as the filament goes through the extruder, causing inconsistencies in the amount of material extruded and lowering your print quality. Different options are available such as SpaceSaver bags, large tupperware containers, dehydrators, desiccant packets, etc. Designs such as the one used here seem to work especially well, but I just use SpaceSaver bags like these with desiccant packets inside.

Consider printing a lubricator for your filament such as this one from Thingiverse. It will protect your extruder and can increase the quality of your prints no matter what type of filament you are printing. It wipes away dirt and dust and causes less friction as the filament moves through the extrusion system.

Make sure your filament is kept neat and untangled. Filament that gets tangled can damage your extruder, cause underextrusion in your part or even cause a part to fail.

Spend some time getting to know each filament type, brand, and even color you buy. Each will be different and require different settings. Print off a few benchys and calibration prints (look on thingiverse for calibration cube, benchy, temp tower, and calibration test to start with). After each of these test prints, look at what issues they may have and make adjustments in your slicer. Some common places I adjust include extrusion temperature, retraction speed and distance, flow rate, and cooling percentage. This process will use up some filament and time, but will make the rest of the filament print much better and you will end up saving filament in the long run by avoiding ugly and failed prints.

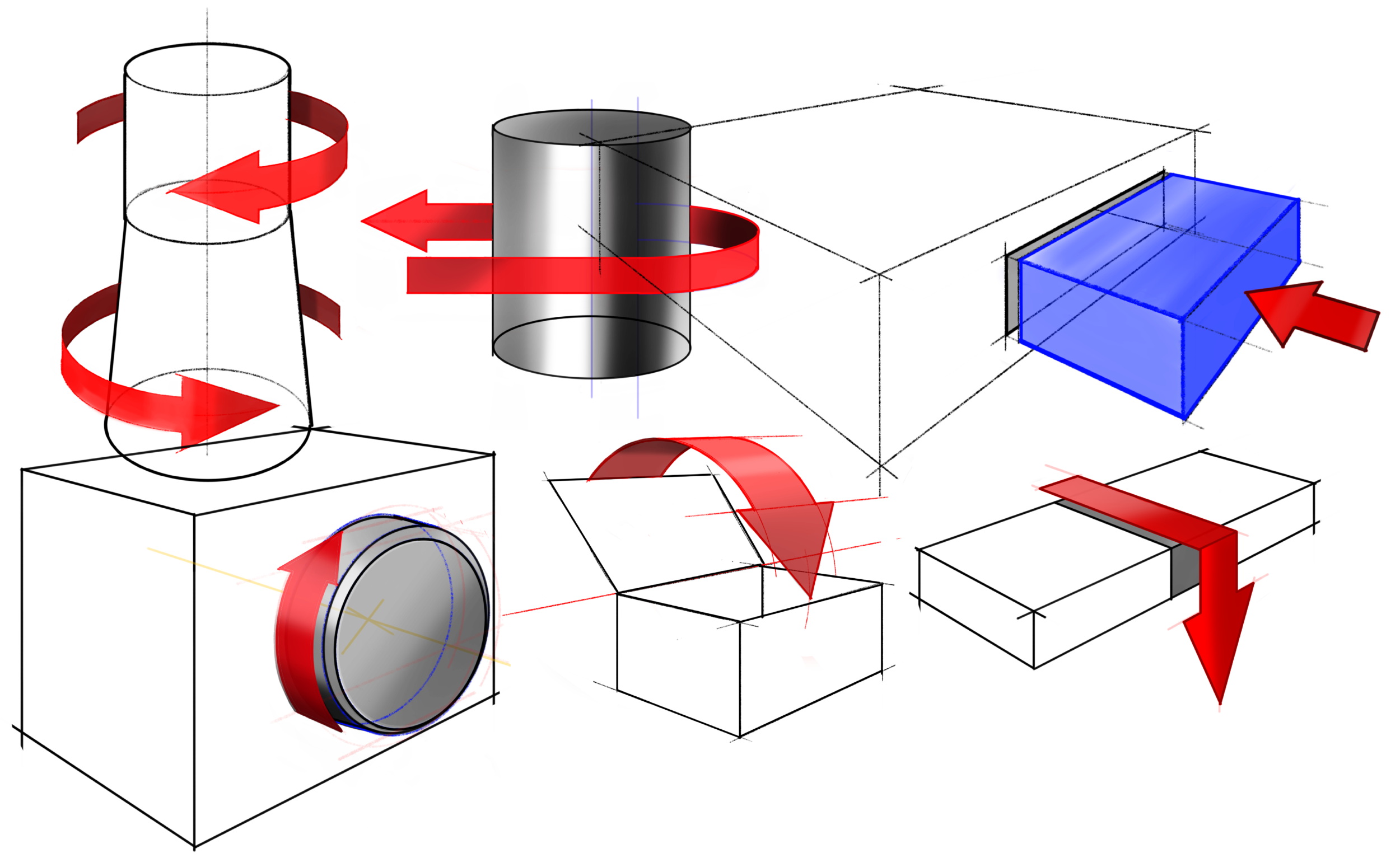

Design with filament in mind. Be aware what filament will help you accomplish your design purpose and plan for the weaknesses that come with it.

Check your filament manufacturer’s website for suggested settings. Many manufacturers will give a range of extruder temperatures and bed temperatures that will work as well as other tips for printing with their specific filaments. They want you to succeed and make good prints so you keep buying filament from them!

PLA

PLA (Polylactic Acid) is a thermoplastic, and a bioplastic, meaning that it is derived from renewable resources such as corn starch or sugar cane. It is perhaps the most commonly used filament type and considered a great beginner filament because it is very easy to print and get a good bed adhesion with, is inexpensive, and can accept a wider margin of user error while still producing adequate results. PLA has a low melting temp and can be printed at high speeds to create models rapidly. Different variants of PLA such as PLA+ or Silk PLA can be used to achieve desirable qualities like greater strength or a better surface finish. I use this material when I need to create quick turnaround proof of concept prints or when I’m creating an artistic piece.

Benefits:

Can use faster print speeds, allowing for models to be completed more quickly.

Relatively easy to print.

Prints at low temperatures.

Inexpensive. ($)

Drawbacks:

Susceptible to moisture, temperature, and UV light

Difficult to sand down- Gums up and doesn’t leave the best surface finish

My Settings:

Go-To Brand: Overture

Print Speed: 60-100 mm/s

Nozzle Temp: 200 Degrees C

Bed Temp: 60 Degrees C

Adhesion: hairspray

Retraction: Yes

PETG

PET (polyethylene terephthalate) is the most used plastic in the world. It has found use in textiles, consumer products, and medical industries, among others. Its most iconic use is as plastic bottles and containers for tupperware, soft drinks, water, and more. PETG is a derivative of PET that introduces glycol to the formula to stop crystallization and lengthen polymer chains. It brings incredible strength and a good amount of flexibility to a model. Its properties are similar to ABS but tends to be easier to print with (ABS is a commonly used filament that has great material properties, but tends to need an enclosure to contain particulates released in the extrusion process and to regulate ambient temperature to prevent warping of the part. PETG doesn’t have these issues so I prefer to use it instead). I use this material when I create functional parts or parts where strength is needed. ***Do not print PETG on bare glass. PETG, unlike other filament types, can bond to the glass and break it when you remove the part. Always use a release layer such as blue painters tape.***

Benefits:

Strong parts

Has a good bend to parts

Naturally food safe (NOTE: other factors of your printer may make prints not food safe)

Impact and chemical resistant

Recyclable

Able to be sanded

Drawbacks:

Slower to print than PLA

Not all printers can print it (Make sure your printer can go to a high enough extruder temperature)

More expensive than PLA ($$)

My Settings:

Go-To Brand: Overture

Print Speed: 40-60 mm/s

Nozzle Temp: 237 Degrees C

Bed Temp: 75 Degrees C

Adhesion: blue painters tape

Retraction: Yes

Flexible

Flexible filament can actually be broken further into several different material types: TPU (Thermoplastic Polyurethane), TPE (Thermoplastic Elastomer), PCTPE (Plasticized Copolyamide Thermoplastic Elastomer), and Soft PLA. In simple terms, normally it is made of a hard plastic mixed with a rubber, although the exact components can differ. Though each requires a different temperature setting, the general concept is the same. The flexibility and strength that it has can open new possibilities. Adjusting the amount and type of infil used, as well as actual part specifications can change the amount of flexibility a part has (think of trying to squish a large rubber block vs stretching a rubber band). I use this material for special cases that require a softer or more flexible material.

Benefits

It's flexible! What else do you need?

Has good strength

Drawbacks

Very susceptible to moisture in filament form

Can be tricky if you don’t have a direct drive extruder (extruder is attached directly to the hot end instead of a PTFE tube)

Not all printers can print it (Make sure your printer can go to a high enough extruder temperature and has a heated bed)

Prints very slowly

More expensive than PLA ($$$)

Difficult to print with supports

My Settings:

Go-To Brand: 3D Solutech

Print Speed: 30-40 mm/s

Nozzle Temp: 200 Degrees C

Bed Temp: 60 Degrees C

Adhesion: blue painters tape

Retraction: No

The three filaments mentioned above are just a taste of available filament types. After you master them, get on Amazon, Google, and other sources and learn about what other filaments might be useful to you. As you learn how to use these and other filaments, your ability to create anything you want will increase. You will be able to create useful and beautiful parts, avoid part failures and printer damages, and save time and effort.

To cite this article:

Hawkins, Garrett. “3D Printer Filaments: Definitions, Applications, and Tips.” The BYU Design Review, 7 May 2020, https://www.designreview.byu.edu/collections/3D%20Printer%20Filaments:%20Definitions,%20Applications,%20and%20Tips.